Instant pasta lines for a sustainable and healthy food

Energy saving and environmental protection mean a lot to Storci. We have decided to reduce the consumption of energy and water for cooking pasta with instant pasta systems, offering consumers quick and easy to prepare pasta. Since ancient times, pasta has always been an essential element of man’s diet. Over the centuries, its ability to adapt to changing lifestyles has remained unvaried. It is a natural, versatile product and adapts to everyone’s taste. When it comes to pasta, Italians are very traditional and know by heart all the steps for a perfect cooking.

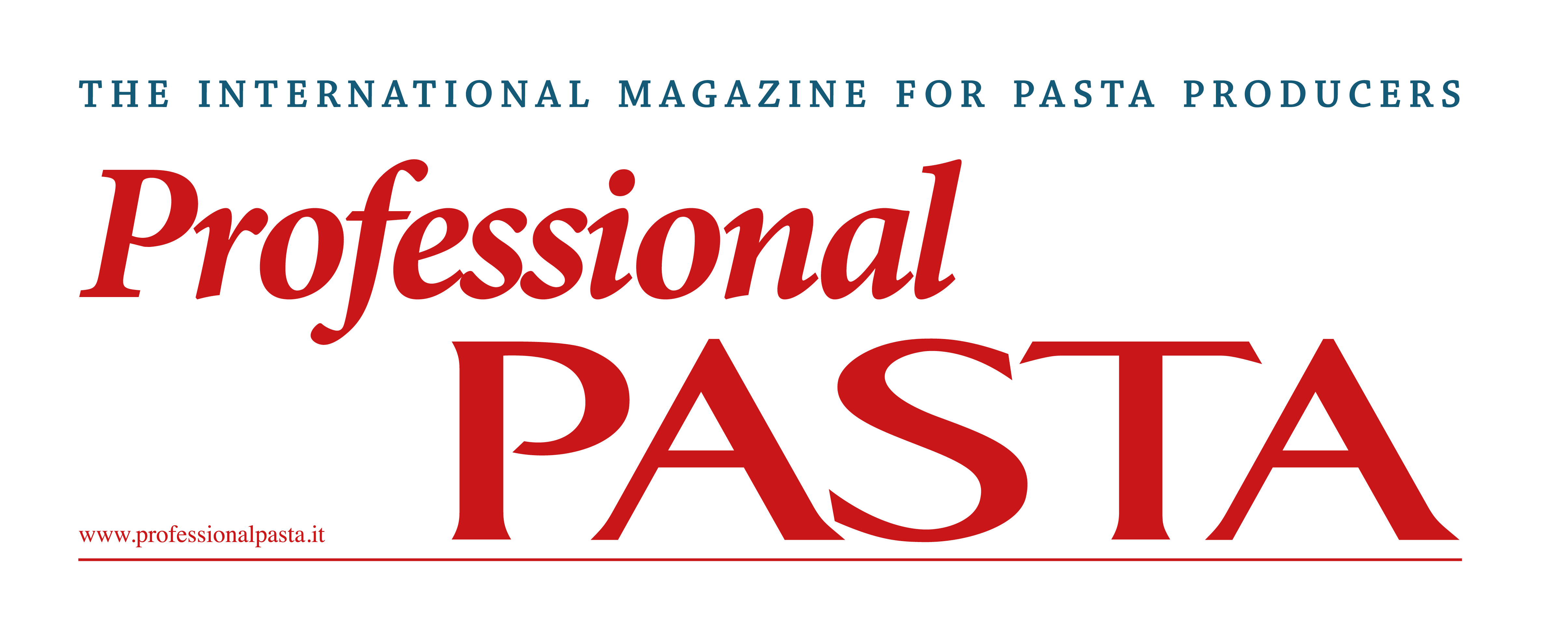

Currently, however, the water emergency is becoming increasingly pressing; thus, it is essential to link the concept of pasta to sustainability and environmentally friendly cooking methods. Our instant pasta lines create a new, handy, healthy, and tasty product, ready in 3 minutes. Dehydrated pasta and sauce, in many different flavours, to get a ready meal at the office, at home, and suitable for everyone, workers, children, health-conscious people, vegetarians etc. Convenient and easy to prepare, instant pasta is cooked using some hot water and fuel. While cooking 100 g of traditional pasta requires 1 litre of water and a lot of heat (to heat the water and keep it boiling for about 10 minutes), instant pasta is pre-cooked and requires about 300 ml of boiling water without the need to keep it boiling. The savings are both in the smaller amount of water and in the preparation, which does not require boiling in a pot. It’s less messy and you can prepare itanywhere there is a kettle or microwave. Storci Instant Pasta System is a complete system for producing instant pasta and provides a full solution for entering this dynamic and innovative market. Our extended offering ranges from small semi- automatic lines to large automatic systems. It is possible to integrate the system into an existing dry pasta line, with low costs and great advantages. In addition to production, we offer a series of associated services, from packaging to global consulting.

Subscribe to the magazine to read the full article